Flexible Moldings

Seneca’s SignatureFlex™ flexible moldings product line is designed for curved architecture and flooring applications. It is the perfect companion to our quality hardwood transitions. Manufactured out of polyurethane material, flexible moldings provide a strong, durable, cost effective alternative to custom wood applications. SignatureFlex products are temperature and water resistant and will not rot or swell.

Molding profiles can be ordered either straight or pre-curved. Straight moldings have some flexibility limitations so pre-curved moldings may be the best solution for tight radius applications. Flexibility depends upon several factors such as size, shape, direction it will be bent, and application. Pre-curved moldings for tight curves remain somewhat flexible and will be adjustable for minor variations. Pre-curving requires a template and will be quoted as a special order.

All profiles are sold unfinished only. Those with a smooth surface can be painted after installation. Those with a wood-textured surface and can be painted or stained and finished after installation. Finishing after SignatureFlex is installed prevents the coating from fracturing due to flexing of the product. Moldings can also be cut, fitted and fastened in the same manner as real wood and can be used inside or outside.

Contact us regarding the availability of custom products or duplicating existing moldings.

- Standard length is 12’

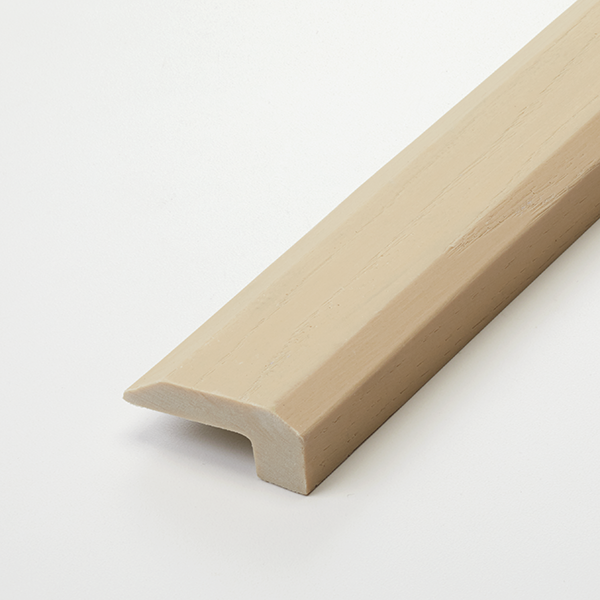

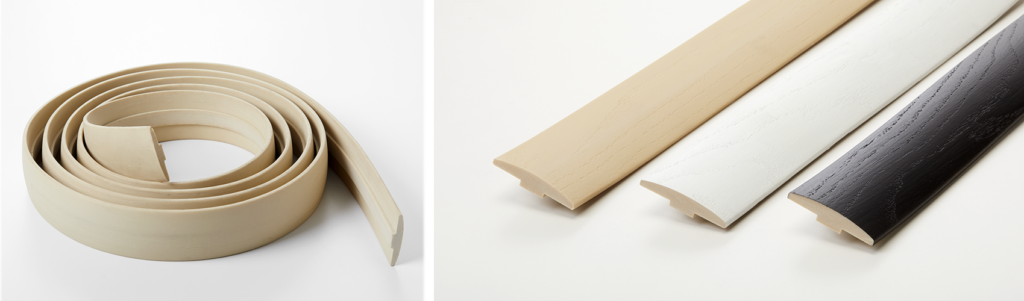

- Sold unfinished and is yellow-beige in color

- Stocked profiles are available in smooth (maple grain) or wood-textured (oak grain) surface options

- Not all moldings are available in all textures/wood grains–contact us for profile availability options

- After installation the molding may be painted or stained, then finish applied (if staining, oak grain will show more texture than maple grain; using a gel stain is recommended)

- Available in straight lengths or pre-curved for tight radiuses

- No additional cost for pre-curved moldings

- Packaged in coils

- No minimum order size

- Custom orders may not be cancelled or returned

RETURN POLICY

- Custom SignatureFlex orders may not be cancelled or returned. It is the responsibility of the customer to ensure that the molding purchased is designed for their particular installation prior to ordering.

- To return a defective product, contact us for a Defective Material Report. Upon approval, a Return Authorization will be issued for the product to be returned and inspected. Valid claims will be issued full credit.

- To return a non-custom, non-defective product, contact us for a Return Authorization Number. The returned profiles must be in good condition and will be subject to a 20% restocking fee. Any credits issued will be applied to the original purchaser’s account.

- All returns must be shipped prepaid freight via UPS or FedEx.

- Call 800-228-6671 or email sales@senecamillwork.com with any questions.

WARRANTY

Seneca Millwork warrants for a period of one year its SignatureFlex moldings to be free from defects in materials and workmanship. We will repair or replace any molding that was sold by our company that failed as a result of defective material or workmanship for this one-year period. Seneca Millwork will also warrant SignatureFlex moldings for a period of one year for excessive wear in non-transit, residential, or light commercial areas. SignatureFlex moldings use in transit or heavy commercial areas are not warranted for wear. The stain/finish being used on SignatureFlex moldings are not part of the warranty. SignatureFlex moldings must be installed, maintained, and used strictly in accordance with SignatureFlex written instructions.

SignatureFlex™ Flexible Moldings

(click the photos below for more information)